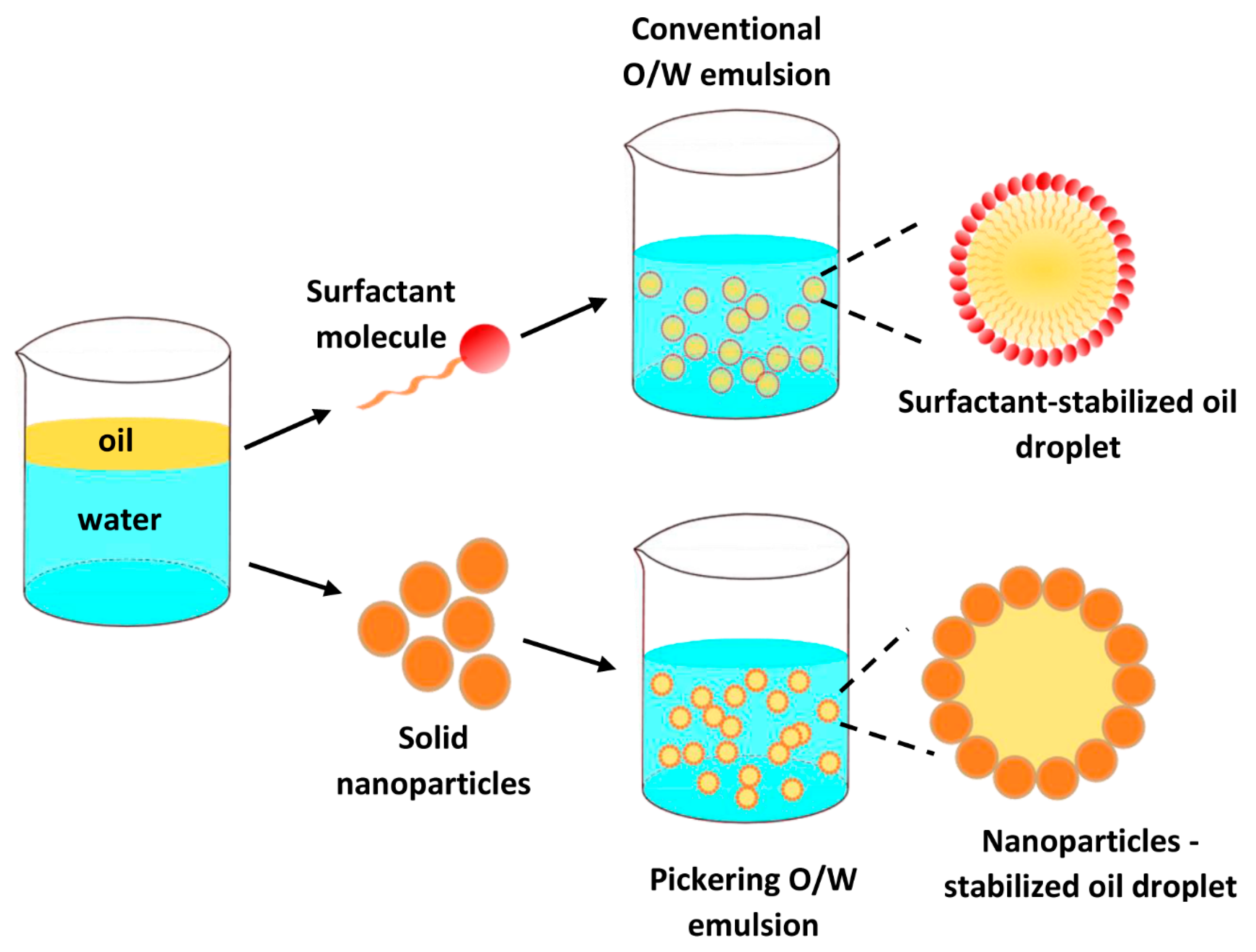

Furthermore, it has been applied to some novel areas, such as oil recovery. Subsequently, Pickering emulsion stabilized by inorganic solid nanoparticles such as silica particles ( 11), polymer lattices ( 12), and clay ( 13) received a wide scope of research attention because of the development of chemical engineering and material science ( 14). Initially, Pickering emulsions did not draw enough attention because of the limitation of materials which showed partial wetting in both phases. These all could provide significantly higher stability. ( 9, 10) presented a fact that the form of a network of particles in the continuous phase can generate a barrier to improving the stability of many gel-like emulsions of moderately high oil volume fraction. ( 9) considered that the capillary pressure due to the anisotropic shapes of solid particles can prevent the interface film drainage. Some researchers have provided different stability functions of particles in Pickering emulsion. Particles can provide a space barrier between the two immiscible phases to prevent droplets' coalescence ( 7) and Ostwald ripening in Pickering emulsions ( 8). There are prime differences in the behavior of the low-molecular-weight surfactants and natural polymers, particles with sizes ranging from just several nanometers to micrometers during the preparation and stabilization of the Pickering emulsions. Hence, the emulsion stabilized by particles was identified and described as “Pickering emulsion”, which can be oil-in-water (O/W), water-in-oil (W/O), water-in-water (W/W) ( 3), or even multiple ( 4– 6). Subsequently, Pickering ( 2) put forward to stabilize emulsions by using nanoparticles and microparticles, which promoted the progress of emulsion research. They are first discovered by Ramsden ( 1) in 1903 that the mixture of wax and water could be stabilized by solids, thus forming emulsions. Pickering emulsions are stabilized by solid or soft nano (micro) particles. Therefore, this review provides a comprehensive overview of the recent advances in the stabilization of Pickering emulsions using diverse food-grade particles, as well as their possible applications in the food industry. Furthermore, they possess distinct interfacial properties and functionalities. Different edible particles are reported by recent publications with distinct shapes resulting from the inherent properties of raw materials and fabrication methods. A food-grade particle is preferred by the food or pharmaceutical industries because of their noteworthy natural benefits (renewable resources, ease of preparation, excellent biocompatibility, and unique interfacial properties). Pickering emulsions, which are stabilized by particles, have gained considerable attention recently because of their extreme stability and functionality. 2College of Food Science and Engineering, Nanjing University of Finance and Economics/Collaborative Innovation Center for Modern Grain Circulation and Safety, Nanjing, China.1Institute of Food Science and Technology, Chinese Academy of Agriculture Sciences/Key Laboratory of Agro-Products Processing, Ministry of Agriculture and Rural Affairs, Beijing, China.All rights reserved.Wei Li 1 † Bo Jiao 1,2 † Sisheng Li 1 Shah Faisal 1 Aimin Shi 1 Weiming Fu 1 Yiying Chen 1 Qiang Wang 1,2 * This work proposes interesting views around tailoring morphology and viscoelasticity of Pickering emulsions by regulating fiber flexibility.īacterial cellulose Cellulose nanocrystals Cellulose nanofibers Pickering emulsions Rheology.Ĭopyright © 2020 Elsevier Ltd. Visible evidence regarding relaxation of long-term structure of droplets is further disclosed by dynamic rheology. For the CNF-stabilized system, depletion effect is dominant, leading to the formation of droplet clusters easily, while for the CNC-stabilized one, repulsive effect plays more important role. Flexible BC nearly has no emulsifying capacity, whereas semi-flexible CNF and rigid CNC can be well used to stabilize emulsions. Thus, these cellulosic nanofibers play different roles during emulsification. In aqueous suspensions, the shortest CNC is rigid, while the longest BC fully flexible, which result in large difference in their dilute-to-semi-dilute concentrations, and in the rheological percolations. Three types of nanocelluloses, including bacterial cellulose (BC), cellulose nanofiber (CNF) and cellulose nanocrystal (CNC), were used to prepare oil-in-water Pickering emulsions with the objective to disclose the effect of fiber flexibility on emulsification.

0 kommentar(er)

0 kommentar(er)